There are quite a few industries that rely on rolls as part of their production processes. For example, the paper, steel, and converting industries all use rolls to create products. What’s more, in order for those in these industries to be able to manufacture products quickly while keeping them consistent, it’s important for the rolls that they use to be aligned properly at all times.

There are quite a few industries that rely on rolls as part of their production processes. For example, the paper, steel, and converting industries all use rolls to create products. What’s more, in order for those in these industries to be able to manufacture products quickly while keeping them consistent, it’s important for the rolls that they use to be aligned properly at all times.

Measuring Roll Parallelism

Over the years, companies that utilize rolls have used different optical systems to measure roll parallelism. They’ve also turned to mechanical methods like contact angle measurement to keep rolls aligned. But the problem with taking these approaches has always been that they take too much time. It’s also often hard to gain access to rolls, which can slow the process down even more and make it difficult to achieve roll alignment.

Proper Measurements

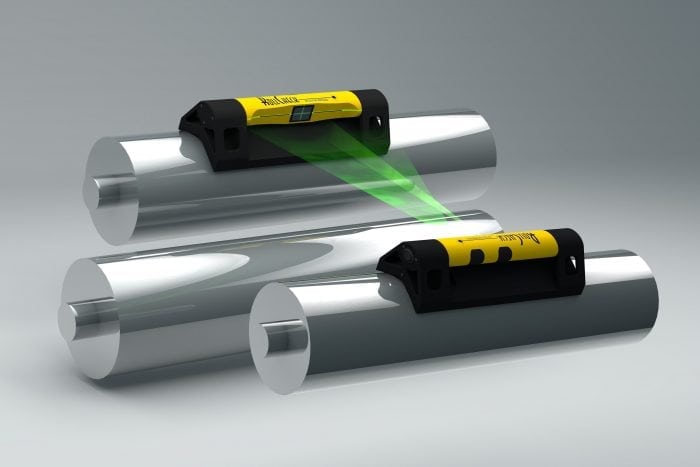

Laser roll alignment has turned these problems into things of the past. Rather than using antiquated optical systems to align rolls, companies are now using laser technology to see whether or not rolls are aligned and adjusting them accordingly. Laser roll alignment allows companies to make rolls more precise than they have ever been while cutting way down on the amount of time that they have to spend looking at their rolls.

An Assist To Your Bottom Line

Outside of saving companies time, laser roll alignment can also save them money. They’re able to produce better finished products when their rolls are aligned the way they should be. They’re also able to save money by keeping their rolls and the parts that go along with them in better shape over the long run. They don’t have to replace parts as often when rolls are aligned.

Seiffert Industrial specializes in providing companies in a variety of different industries with laser alignment services. Call us at 800-856-0129 today to see how our services can help your company.