If you work in an area where machinery is present, you know that if the machines are properly aligned, that’s good, and if they’re not, well… that’s bad. What are some of the bad things that happen when you have misaligned machinery?

Coupling Damage

If and when machines aren’t aligned well, you can expect coupling damage. Bearings may wear out, también, causing the machine to break down. Seals can be damaged, leading to leakage. The shaft can become impaired. All of these things can cost a company both time and money. How do you notice if you have a bad alignment? If the machinery is vibrating in an out-of-the-ordinary way, then you could have trouble. If your energy bills are skyrocketing, it could be because your machines are out of alignment and having to work that much harder just to try and do their jobs. Finalmente, if the product quality of items being produced “isn’t there,” then you’ve probably have a poorly aligned machine.

Shortened Operating Life

Idealmente, you want your machines to be in perfect alignment all the time. Why is this? Bien, this helps increase a machine’s operating life. A good alignment means reliable service that’s also highly efficient.

Should alignment be done using a trial-and-error method? No. It’s too time consuming. These days, it makes sense to utilize modern laser measurement systems to do the job quickly and correctly.

Herramientas de alineación láser

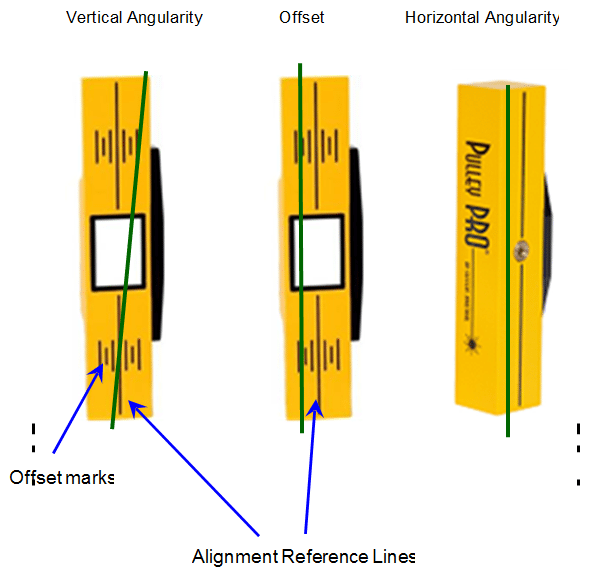

Seiffert Industrial has several laser alignment tools to choose from; Have a look to see what’s available, including the Pulley Pro Green V Belt Alignment Tool and the Pulley Partner Belt & Herramienta de alineación de polea.

Ubicado en Richardson, Texas, Seiffert Industrial can be reached by calling 800-856-0129 or via the online contact form, aquí. Notablemente, all of our products are made domestically in the USA.