Industrial bearings reduce frictional forces between two moving parts by giving a surface something to roll on rather than slide over– they’re crucial for motion applications.

Ideally, you want to get the most life out of your bearings, but there are several reasons bearings fail. What are some of those reasons?

Not Enough or Too Much Lubrication

Most of the time, bearings fail because they’re not properly lubricated. There’s either not enough lubricant, the wrong lubricant, or excessive temperatures have degraded the lubricant. 8 times out of 10, bearings fail due to lubrication issues, so that’s the first thing to check when investigating when/why bearings fail.

Bearings can also fail when foreign substances such as dirt or steel chips get into bearing lubricants or cleaning solutions. The lubricant might need to be filtered. Work areas might need to be cleaned.

Mounting Issues

What about mounting? Bearings should be mounted with a press fit on the rotating ring. Sometimes the rings crack, dent or wear out. Inspect the mounting to see if your bearings are properly or improperly mounted.

Sometimes things get out-of-square, including shaft shoulders, spacers or clamping nuts. Loose fits can cause misalignment, leading to overheating and separator failure.

Miscellaneous Issues

If you see linear wear marks in the axial direction at the rolling-element pitch, there could be false brinelling.

If you notice red or brown stains on rolling elements, raceways, etc., moisture, acid or grease could cause corrosion, and this corrosion is abrasive to the surfaces of ball and roller bea63rings.

Electrical damage could be the cause of bad bearings. Samuti, fatigue due to overloading can cause bearings to not function properly when there’s an excessive preload and/or tight inner-ring fits. Excessive loads and/or overheating can also cause failure.

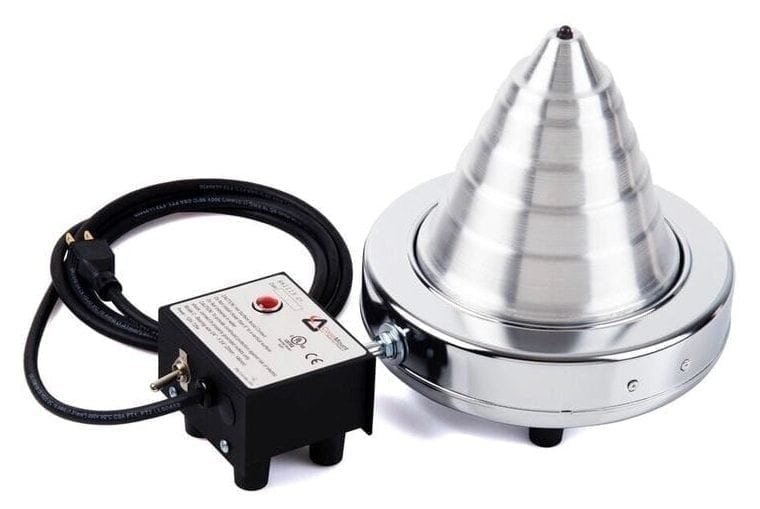

Do you want to keep your bearings in top shape? Seiffert Industrial sells ConeMount bearing heaters, Siin: Lisateabe saamiseks, please call Seiffert Industrial at 1-800-856-0129.