ישנם לא מעט תעשיות המסתמכות על לחמניות כחלק מתהליכי הייצור שלהם. לדוגמה, the paper, steel, and converting industries all use rolls to create products. מה עוד, in order for those in these industries to be able to manufacture products quickly while keeping them consistent, it’s important for the rolls that they use to be aligned properly at all times.

ישנם לא מעט תעשיות המסתמכות על לחמניות כחלק מתהליכי הייצור שלהם. לדוגמה, the paper, steel, and converting industries all use rolls to create products. מה עוד, in order for those in these industries to be able to manufacture products quickly while keeping them consistent, it’s important for the rolls that they use to be aligned properly at all times.

Measuring Roll Parallelism

במהלך השנים, companies that utilize rolls have used different optical systems to measure roll parallelism. They’ve also turned to mechanical methods like contact angle measurement to keep rolls aligned. But the problem with taking these approaches has always been that they take too much time. It’s also often hard to gain access to rolls, which can slow the process down even more and make it difficult to achieve roll alignment.

Proper Measurements

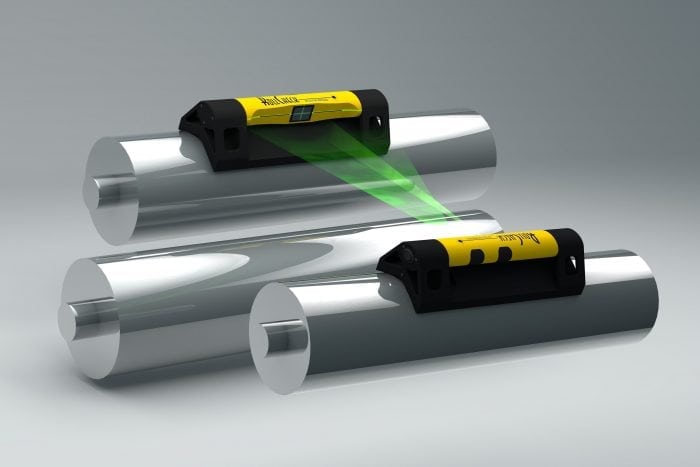

Laser roll alignment has turned these problems into things of the past. Rather than using antiquated optical systems to align rolls, companies are now using laser technology to see whether or not rolls are aligned and adjusting them accordingly. Laser roll alignment allows companies to make rolls more precise than they have ever been while cutting way down on the amount of time that they have to spend looking at their rolls.

An Assist To Your Bottom Line

Outside of saving companies time, laser roll alignment can also save them money. They’re able to produce better finished products when their rolls are aligned the way they should be. הם יכולים גם לחסוך כסף על ידי שמירה על הלחמניות שלהם ואת החלקים כי ללכת יחד איתם בכושר טוב יותר בטווח הארוך. הם לא צריכים להחליף חלקים בתדירות כאשר לחמניות מיושרות.

Seiffert תעשייתי המתמחה בחברות מתן במגוון של תעשיות שונות עם שירותי יישור לייזר. תתקשר אלינו ב 800-856-0129 היום כדי לראות איך השירותים שלנו יכולים לסייע לחברה שלך.