If you have industrial equipment, then you know sometimes it can get out of alignment and that messes with performance… and eventually equipment can become damaged and then there’s downtime– dreaded downtime when you should be working but the machine won’t work and that ruins the schedule and cuts into profits and people are mad about the whole thing. Ugh.

How Electrical Motors and Pumps Benefit Laser Alignment Tools

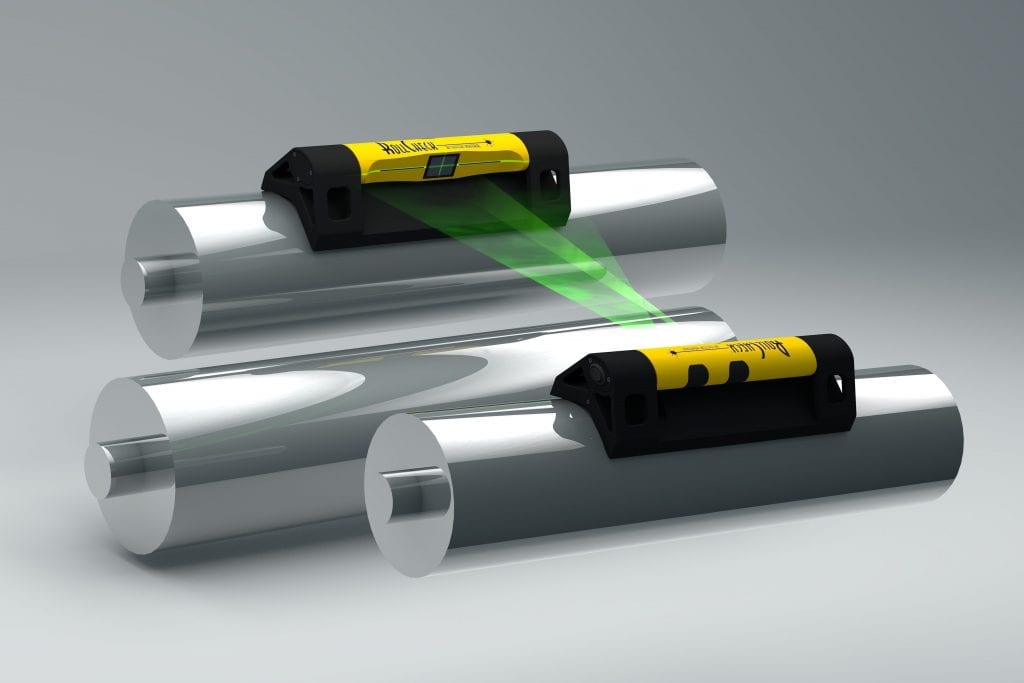

Sometimes electric motors and pumps benefit from motor laser alignment which involves using both laser equipment and special software to measure and then correct the orientation of a motor and/or pump shaft. This, in turn, helps improve accuracy and efficiency so the industrial equipment is working reliably well as intended.

When might a motor laser alignment be in order for a piece of industrial equipment? If you notice vibration levels that seem abnormal, that could be a sign your machine is out of alignment and therefore its components could be wearing down and not working together properly. You might also notice your energy consumption is “up” because your machine (and its electric motor, specifically) is having to work harder since it’s out of alignment. If your energy bills have been out of whack, chances are your equipment needs better alignment.

Motor laser alignment results in your equipment performing better, with increased energy efficiency. It also helps your equipment last longer and, ultimately, leads to increased productivity. Keep your equipment aligned with the aid of motor laser alignment.

Curious about motor laser alignment options available today? Please call Seiffert Industrial at 1-800-856-0129 to discuss motor laser alignment products and tools. Seiffert Industrial is located in Richardson, Texas, and has been in business since 1991. If you have time, view some videos showcasing the various products Seiffert offers, here.