Machinery can run for hours and hours, right? Some places utilize machinery that has been running not just for hours or days or weeks, but for many months or for many years with little downtime. With that in mind, machinery can wear down and eventually fail. In particular, things can happen such as misalignments of a machine’s v-belts and/or sheaves.

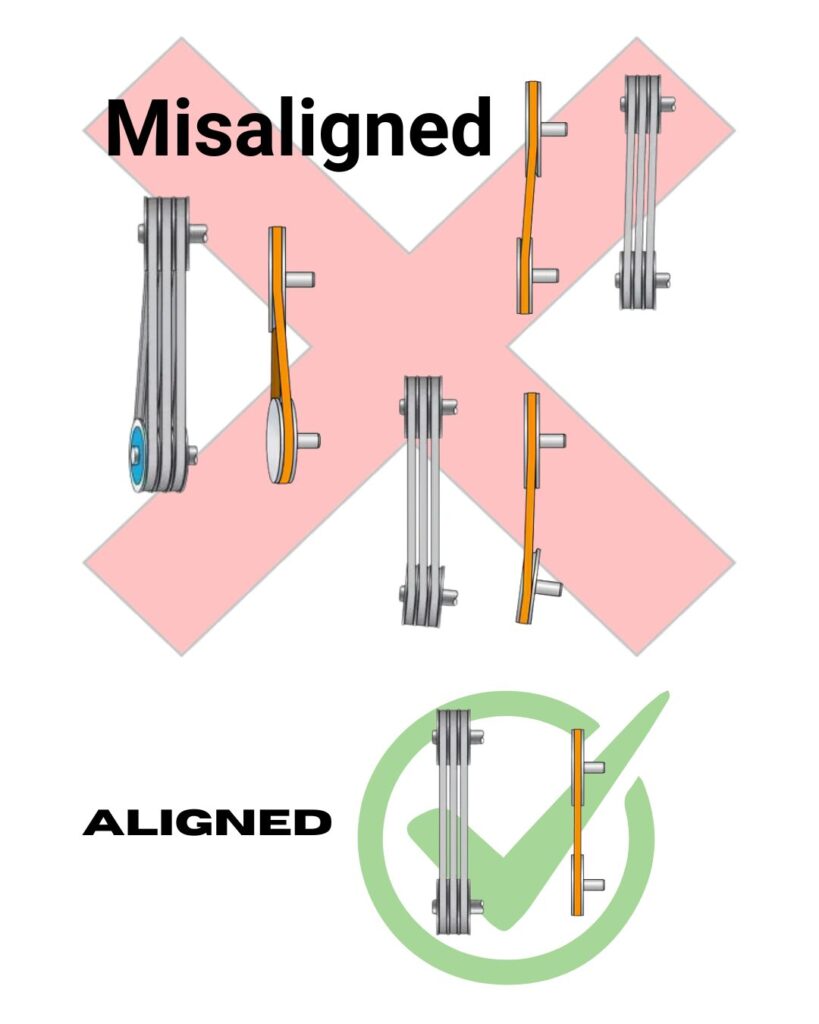

Misalignments are not good for machines. Whether angular or parallel, misalignments will definitely increase both wear and fatigue on a belt. If a belt is ruined, there goes production time as everything has to be shut down, and time is money!

Therefore, it’s always a good idea to have someone looking at machinery with a particular focus on its alignment. What are some ways workers can tell if a machine is experiencing a misalignment?

Warning Signs of Misalignment

Well, if a belt fails prematurely, before it’s ever expected to, then there’s probably a misalignment. Stress can cause a belt to tear and fail.

What if there’s premature and/or uneven sheave wear? That’s another indicator of a misalignment.

Take some time to listen to a machine. Does it sound normal or not? If you can hear a squealing noise or a chirping sound then you probably have a misalignment because there’s a slippage between belts and pulleys.

How about excessive vibration? When belts or sheaves are misaligned you can expect excessive vibration.

Look down at the foot of a machine for belt shavings. That “belt dust” could indicate there’s a misalignment.

If you notice a belt looking stretched in an unusual way, that could be due to a misalignment that’s causing it to stretch out too much. There could be a problem with the tension.

Tensile failure (due to an uneven cord loading) may also indicate a misalignment.

There are many reasons for misalignments. If you want to check for them, and correct them before they get out of hand, Seiffert Industrial has helpful and handy laser alignment tools to help make your job easier! Call Seiffert Industrial at 1-800-856-0129 for more information.