Over the years there have been many ways to align two or more rotating shafts into a straight line. Perhaps you’ve heard of some of them– calipers, comparatori, feeler gauges, optics or straight edges were/are some popular methods. Detto ciò, today’s preferred, modern way to align shafts would be a laser shaft alignment tool which involves using lasers looking at both the vertical and horizontal plane to make sure things are rotating on a common axis.

How it Works

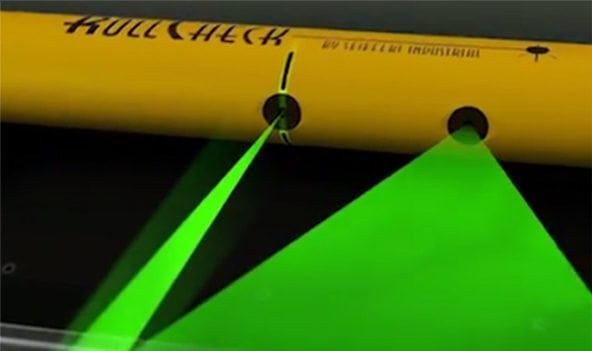

Laser tools use emitters and sensors which are mounted to shafts in such a way that the emitter can shoot a laser across the shaft to the sensor using a single beam laser light set-up. Detto ciò, sometimes both sides can emit lasers while also acting as sensors– aka a “dual beam laser.” Either way, thanks to laser beams, the shaft can be rotated to find the center lines of rotation between the two shafts in a precise and accurate way.

Laser tools show what’s going on (oftentimes graphically) via a display unit or tablet. Misalignments can be identified and rectified thanks to vertical or horizontal adjustments. Associated software takes into account allowable tolerances.

Many companies today rely on laser alignment tools to check their alignments annually, as well as to check on recent equipment installs to make sure they’re functioning as intended a couple months down the line. Idealmente, companies do not want their rotating machinery to break down– and if there are misalignments, breakdowns can easily happen. No bueno! Properly aligning shafts helps machinery work well, making less noise and using less lubricant. Nel frattempo, the machines will last longer– a nice bonus.

If you want a tool to use for alignment that’s fast, easy and accurate, then call Seiffert Industrial of Richardson, Texas, a 1-800-856-0129 to ask about laser alignment tools. You can also email info@seiffertindustrial.com.