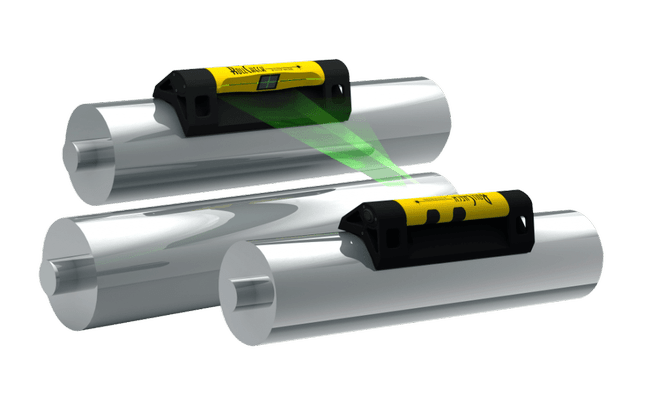

With some jobs, you can use a standard level. However, there are many benefits to using laser leveling tools. Laser tools use a beam of light to make a 100% straight line reference along a surface. More accurate than traditional levels, laser leveling tools can align elements over a long distance.

Laser Leveling Tools

If and when you are surveying, it’s a good idea to use laser leveling tools. These tools can check the elevation or slope of a large area. This can be helpful when you’re working on building a foundation, dealing with flooring and/or other surfaces that you need to be level. Vertically-speaking, these tools are also helpful when installing drywall, doors, windows and preparing landscaping projects.

Laser levels help eliminate human error in most cases. You don’t have to hold them steady. One person instead of two can operate the level. It makes getting the job done quicker. You can use the projection (from the laser) to mark up the wall as needed. These tools are flexible and can be used in a wide range of applications in many different industries.

Providing excellent accuracy– within 1/16th of an inch at 100 feet– laser levels are used when you want to be efficient, quick and precise. Whether handheld or mounted on a rod or piece of equipment, laser levels project a line onto the surface which can then be marked as needed. Laser level tools are generally lightweight and involve easy-to-read digital displays which are often compatible with networked data systems.

Curious to know more about how versatile laser levels could improve your business? You can call Seiffert Industrial at 1-800-856-0129 for more information.

Seiffert Industrial works with many industries, including oil, gas, refining, power, chemical, machining, marine, pulp, paper and steel, among others.