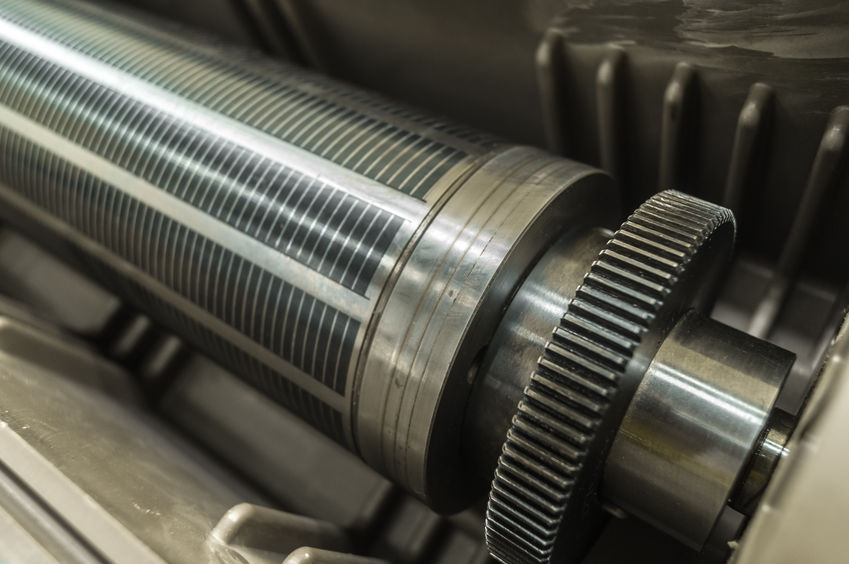

You work with machines and with rotating machinery, if you’ve got misalignments then you’ve got problems. Misalignments mean downtime or worse– the need to replace the machine much sooner than you had hoped, right? When you’re experiencing rotating machinery failures, there’s a good chance that misalignments are the cause. Misalignments cause premature bearing, coupling and shaft failure and that’s not what you want.

Misalignment Leads to Shutdowns

Businesses are in business to meet their customers’ needs and to make money. Anything that gets in the way of doing those two things can cause trouble. Obviously, you want to be both profitable and productive, but if you’ve got a misalignment issue with a rotating machine or two, that can shut everything else down for minutes, hours or even days.

Shafts should be correctly aligned, running along a common centerline. That said, when two shaft centerlines run alongside but not in the same line thanks to an offset on the vertical/horizontal plane, you’ve got a parallel misalignment. And when the motor and the driven equipment are set at an angle to each other making the centerlines cross, you’ve got an angular misalignment. Perhaps both of these problems are occurring so you’ve got a combination misalignment.

Correcting Misalignments

What can you do when you’re experiencing misalignments? Use laser alignment tools to get your rotating machinery back into alignment so it’s working as intended. When you do this, you reduce the risk of machine failure, and you’re also going to reduce costs in the long run.

Seiffert Industrial can help you figure out what laser alignment tool or tools you might want to acquire in order to deal with misalignments on the machinery where you work. Please call Seiffert Industrial at 1-800-856-0129 and tell us about your specific machine(s). Hopefully, we can help you solve your problem quickly with the right alignment tool(s) sent out a.s.a.p.