Apabila tulang belakang seseorang tidak dapat diselaraskan, mereka mungkin mengalami sakit belakang, keseimbangan masalah dan kesakitan. Oleh yang demikian, Mereka melawat kiropraktor untuk menyesuaikan tulang belakang mereka kembali ke kedudukan idealnya sehingga berfungsi seperti yang dimaksudkan. Sekarang bagaimana dengan mesin? Mereka tidak mempunyai tulang belakang, per se, but they certainly do have many components working together to accomplish tasks… and sometimes machinery goes out of alignment.

Causes of Misalignment

Why does misalignment occur with machinery and various mechanical equipment? Baik, usually there are two rotating shafts that should be working together in sync but they end up no longer parallel to one another, offset or angled wrongly at the coupling. A parallel misalignment occurs because the two shafts do not exist on a parallel plane– the center line is offset.

In addition to parallel misalignments, there are several other misalignments including horizontal (when the angle of one shaft is different than the angle of the other on a horizontal plane) and vertical (when the angle of one shaft is different than the angle of the other on a vertical plane), as well as horizontal angled and offset misalignments when one shaft is both offset and angled differently than the other along a horizontal plane and vertical angled and offset misalignments (one shaft offset and angled differently than the other along a vertical plane).

Secara khusus, misalignments occur due to things such as pipe strain, thermal expansion, wear (causing sheaves to deform) or baseplate settling irregularly (forming a soft footing). Human error as well as inaccurate assembly of components are also two reasons misalignments occur.

When misalignments occur, you get unsteady motions and movements. Oftentimes bearings and/or couplings become stressed. Seals get damaged. The machinery can end up not even working at all if the misalignment is seriously misaligned!

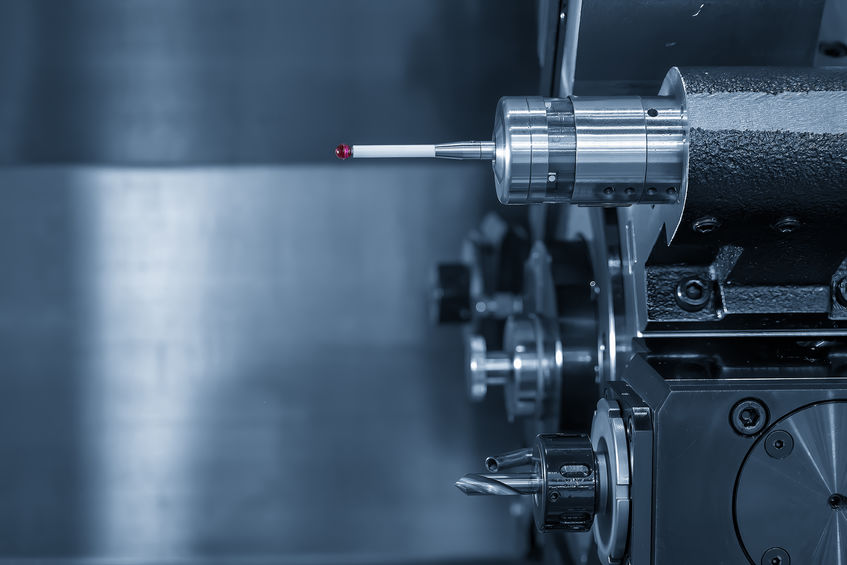

Syukurlah, there are alat-alat penjajaran laser that can help machine and equipment operators measure and then correct alignment. These tools utilize modern technology to offer precise measurements. If you’d like to learn more about laser alignment tools, please call Seiffert Industrial at 1-800-856-0129.