Features

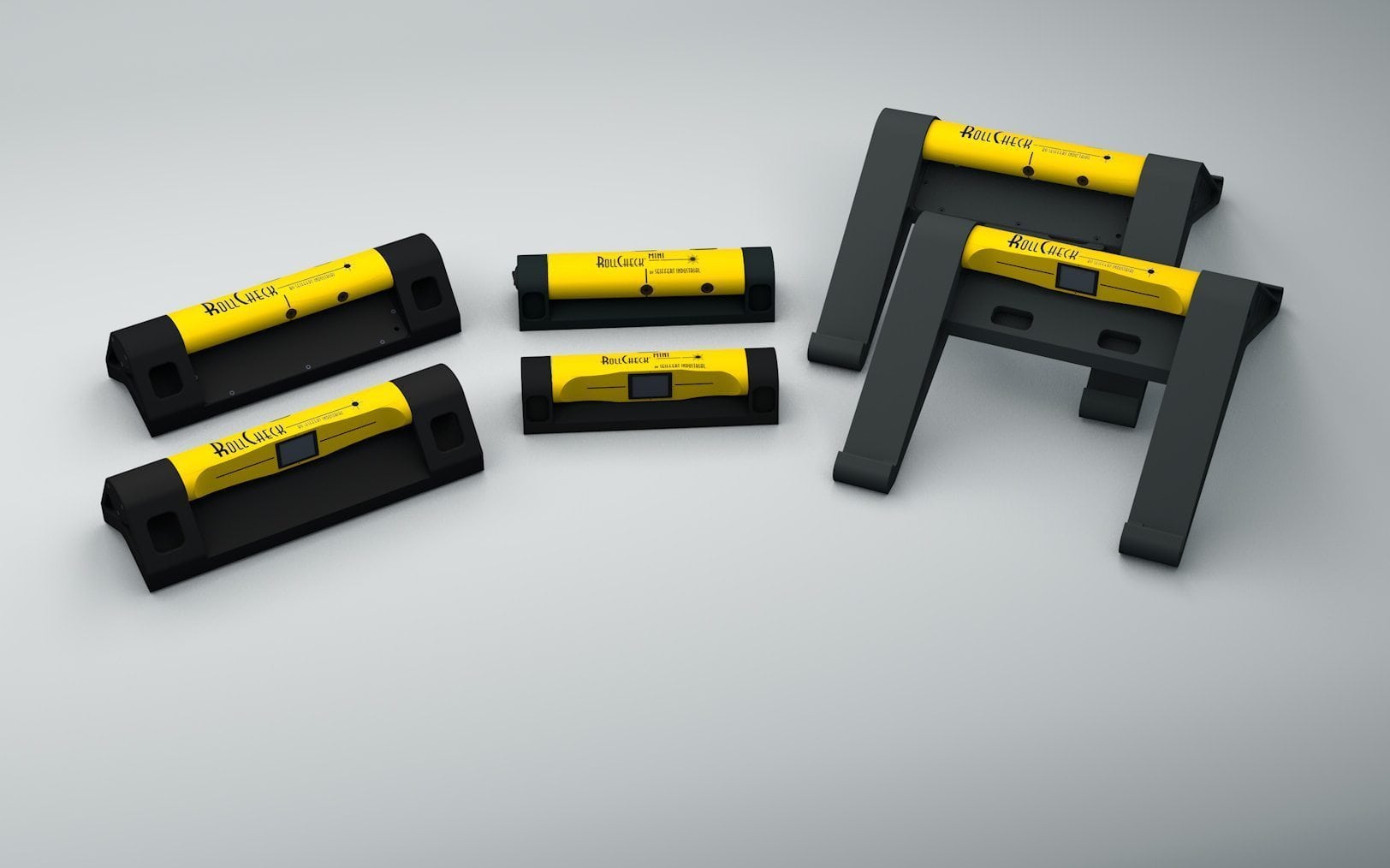

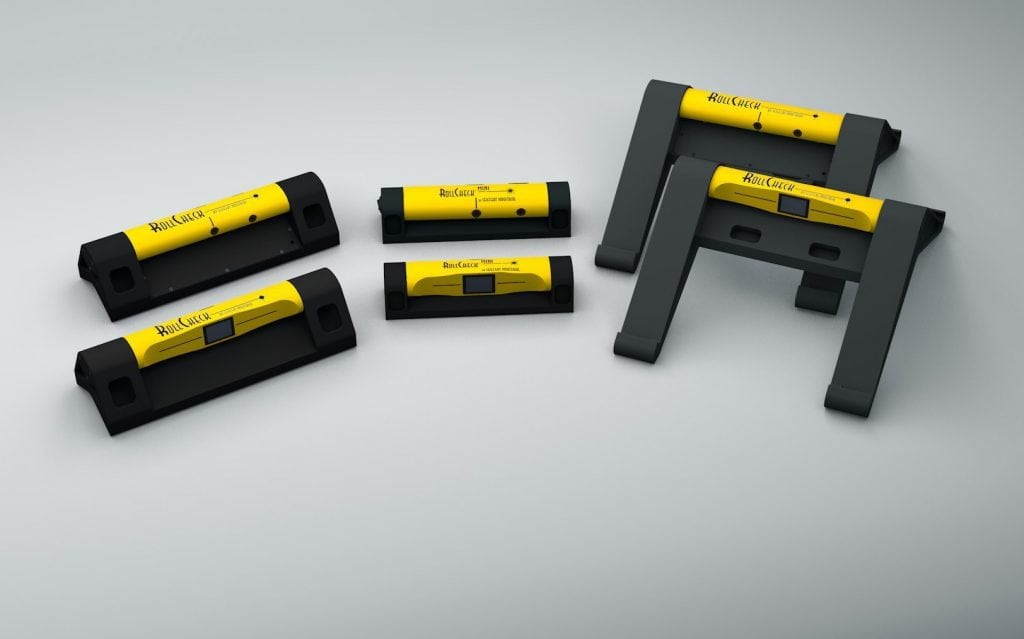

RollCheck MAX Laser Roller Alignment System Features:

- Medium to Large Machine Design

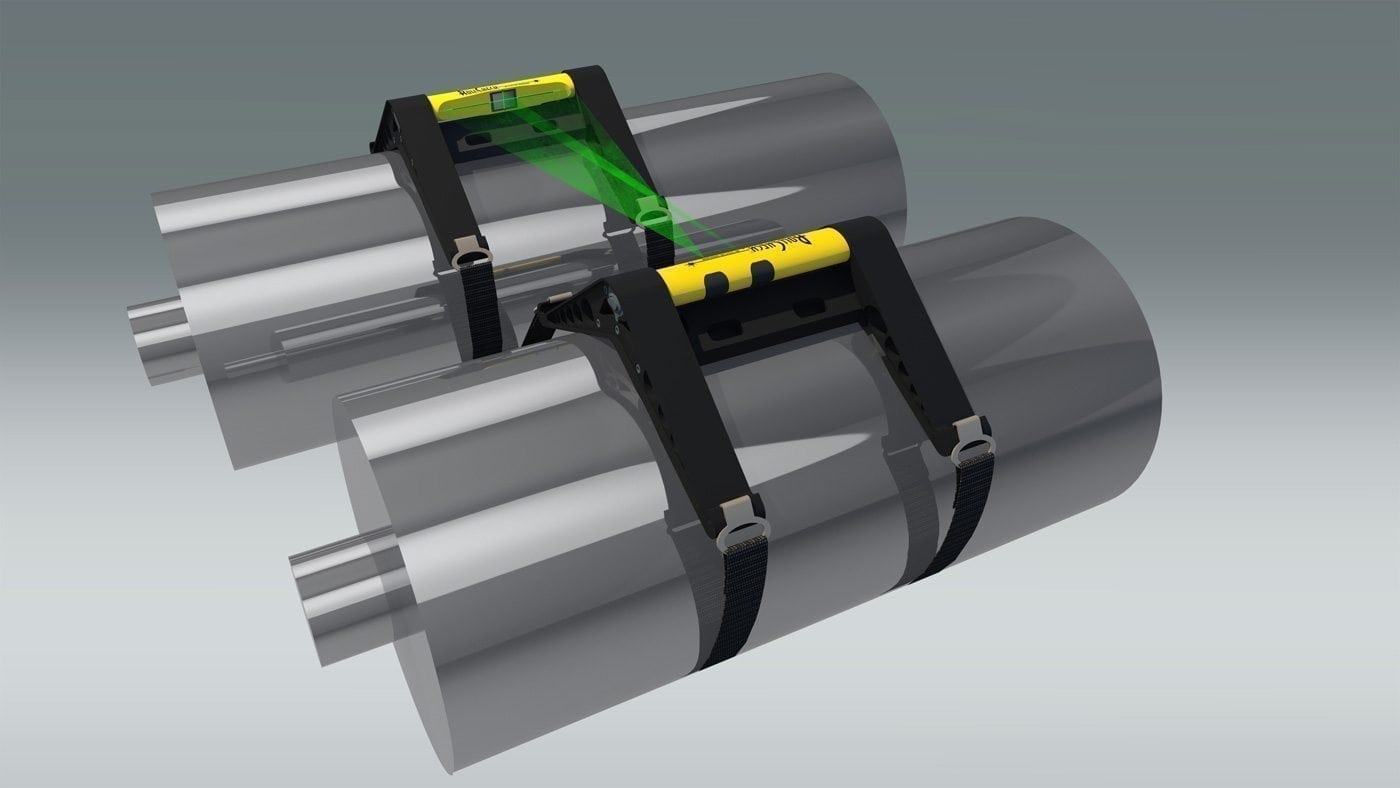

- Bright GREEN laser lines

- Rechargeable lithium ion batteries

- Reduces down time and product waste due to misalignment of rolls

- Increases production with proper alignment of rolls

- Compact design, fits into small spaces

- FAST and EASY to use

- No training required

- One-person operation

- Facilitates more frequent roll checks

- Pays for itself quickly

- Uses proven reflected laser beam technology

- Parallel Roll Alignment, utilizing the RollCheck® Laser Roller Alignment Tools to measure and correct vertical and horizontal angle between 2 rolls

RollCheck® is a laser roll alignment tool that facilitates accurate visual alignment of process rolls during replacement operations. The Laser Transmitter is mounted to a stationary roll that transmits two green laser lines to the Reflector positioned on the roll to be moved.

The operator then is able to view both the vertical (pitch) and horizontal (parallel) angles and accurately adjust the roll into parallel alignment. RollCheck® is suitable for aligning rolls of most diameters that are spaced from 6” (152 mm) to 10 ft. (3 m) or more apart. It also can be used to align and measure crowned rolls as well.