Features

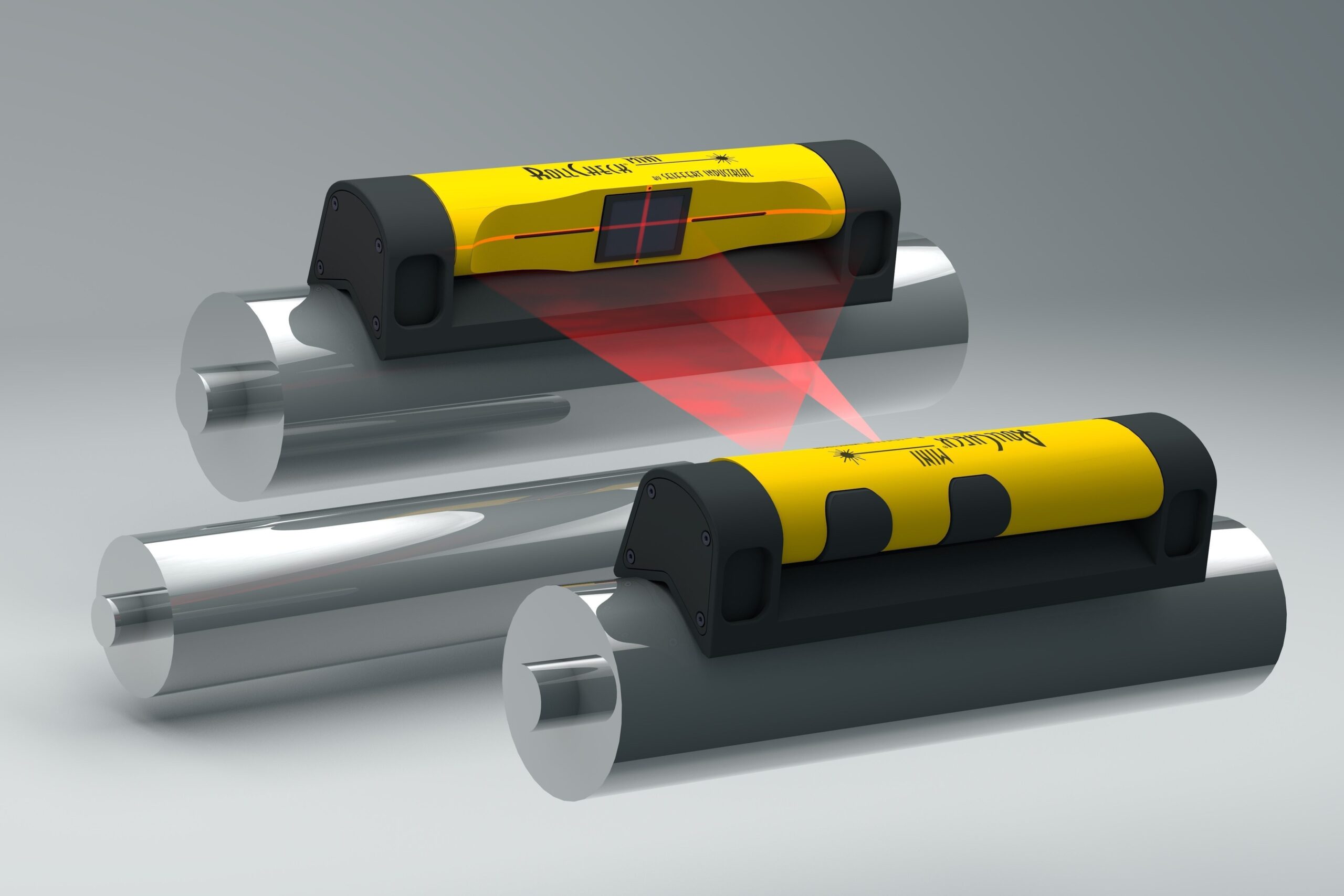

RollCheck MINI Advantages & features:

Reduces down time and product waste due to misalignment of rolls

Increases production with proper alignment of rolls

Compact design, fits into small spaces

Fast and easy

No training required

One-person operation

Facilitates more frequent roll checks

Pays for itself quickly

Parallel Roll Alignment, utilizing the RollCheck® MINI Laser Roll Alignment Tools to measure and correct vertical and horizontal angle between 2 rolls.