Agradeça às nossas estrelas da sorte pela tecnologia laser – ela ajudou no alinhamento da correia para fazer com que muitas máquinas funcionassem melhor! Se as máquinas estivessem ou estão desalinhadas, você esperaria contas de eletricidade mais altas, e isso reduz os lucros. Mas ter o alinhamento adequado, graças à tecnologia laser? Bem, that can actually save your company some money– up to 10% in energy costs, por exemplo.

Laser Technology Extends Service Lives

Laser technology helps belts stay so well aligned that their service life is extended. Lasers are so accurate that they enable your belts to work almost perfectly. When belts are aligned well, there’s less risk of overheating or secondary damage. Noise levels are reduced. Belts last longer (as do pulleys and bearings). Machines are available more often (less downtime) and have less serious breakdowns. All of this leads to a safer working environment and greater overall savings.

Laser Technology Help Prevent Misalignments

Keep in mind that transmissions with belts can be sensitive due to misalignments. Reduced efficiency can end up costing your company a lot of time and money. Misaligned belts also wear out quickly and then need to be replaced at your expense. Tension can become uneven over the entire width, and that’s not good. Nos velhos tempos, alignment might have been done with people’s eyes– and that could be inaccurate. But the “laser focus” of laser devices? That’s putting technology to good use– lasers are like the sharpest eyes around. They can see in a way that humans cannot.

Lasers are modern and mean you’ll need fewer spare parts for your machinery. You’ll use less energy. And you’ll have less unscheduled downtime. What’s not to like?

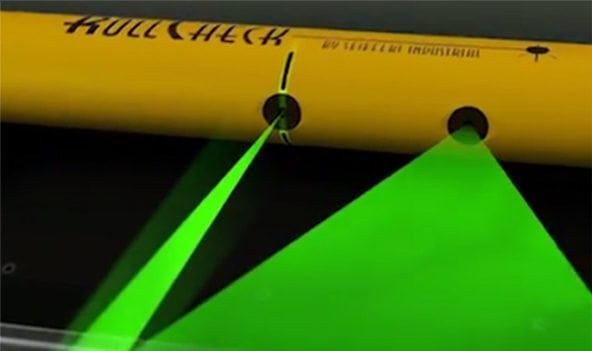

Seiffert Industrial de Richardson, Texas, sells various laser alignment tools. Para mais informações, please call Seiffert Industrial at 1-800-856-0129.