Think of all the people who go to chiropractors because their backs hurt… and chiropractors use their hands to manipulate the spine “back into alignment” in order to relieve people’s pain. If a person’s spine is in alignment, their body functions well and they can do their daily activities as intended.

For the longest time, work was done by people, but these days more and more work is done by machines. And if they get out of alignment, for whatever reason, problems ensue. This costs both time and money and is not good for companies who want to make sure their machines are always reliable, right?

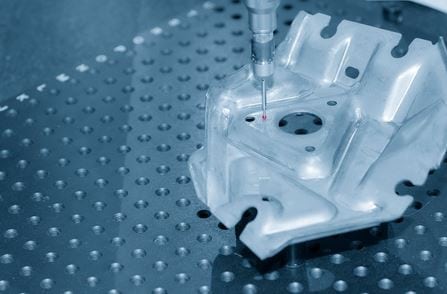

Machines need to be running and running well in order to accomplish their goals. In today’s modern era, if you want to keep machines working their best, utilize laser alignment if you want to increase machine reliability.

Most machines need maintenance over time. The CMMS system records and tracks all asset detail and maintenance work info. It’s in place in order to help maintenance planning be more efficient and effective. That’s good! But what about alignment technology? This is a natural extension to using a CMMS. It adds helpful information regarding the condition of machines that otherwise might go unnoticed… until failure occurs.

Warning Sings of Machine Misalignment

What are some signs of misalignment? Well, high energy use, excessive vibration and unusually hot components could all indicate there are problems with the alignment. Therefore, could grinding noises, load imbalances and rotor bar problems.

If you want to ensure machinery alignment, the solution is simple: laser alignment. It will proactively identify problems early on and mean fewer emergency repairs will be needed. Furthermore, it helps increase the quality of output with less downtime and reduced maintenance cost. Laser alignment provides accurate measurements and is considered error-free.

Any business that depends on machines to function well should invest in laser alignment. For more info, contact Seiffert Industrial at 1-800-856-0129.