The bearings inside industrial machines play a very important role in extending the life of your equipment. These bearings are designed to bear the brunt of the friction that shows up when there are rotating parts inside of machines. In order to ensure these bearings are able to do their jobs, they must be installed properly through the use of bearing heaters. Continue reading to find what bearing heaters are, how they work, and why they’re so essential.

The bearings inside industrial machines play a very important role in extending the life of your equipment. These bearings are designed to bear the brunt of the friction that shows up when there are rotating parts inside of machines. In order to ensure these bearings are able to do their jobs, they must be installed properly through the use of bearing heaters. Continue reading to find what bearing heaters are, how they work, and why they’re so essential.

What are bearing heaters?

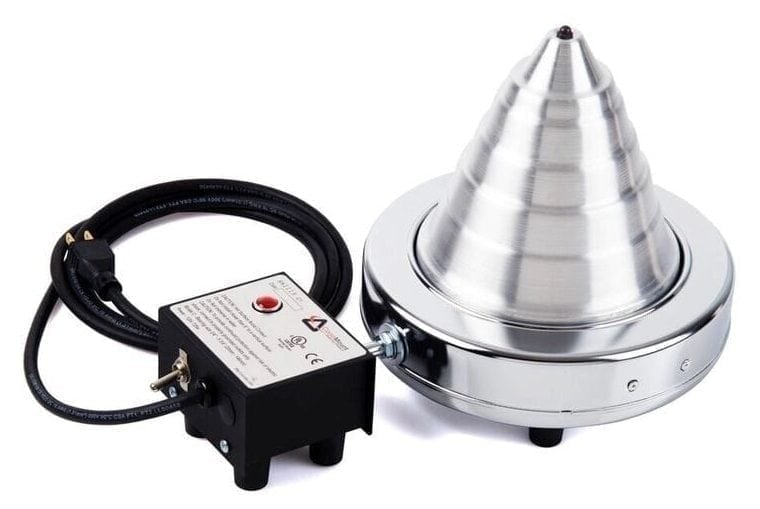

Bearing heaters are devices that utilize heat to help with both the assembly and disassembly of bearings as well as gears, sprockets, and other parts inside of a machine. Products like ConeMount bearing heaters will allow you to generate the heat necessary to prepare bearings and other parts to be mounted or dismounted from a machine.

How do they work?

Although they play a vital role when it comes to keeping the bearings for your machines in tip-top shape, bearing heaters are simple tools to use and don’t require much training. They work by heating up the inner ring of a bearing and causing thermal expansion, which makes it easy to mount and dismount bearings. They often reach temperatures of 230 da 250 degrees Fahrenheit to accomplish this goal.

Why are they essential?

It’s extremely important for any bearings in your machine to be installed properly so that they’re aligned and prepared to deliver the performance you need from them. If you don’t use a bearing heater, there is a good chance that your bearings will break down on you much sooner than expected. They can also cause issues with other aspects of your machines. It’s why you should use bearing heaters to safely heat up your bearings.

Your bearings will last longer and perform better when you put the ConeMount bearing heaters from Seiffert Industrial to the test. Позовите нас на 800-856-0129 to invest in bearing heaters or other products that will help you maintain your company’s machines.