If you own or are in charge of running an industrial business, it’s extremely important for you to maintain all of the equipment that you use. This might seem like common sense, but you would be surprised by how many industrial companies fail to do the proper maintenance on the equipment that they use every day. As a result, they are often forced to deal with costly repairs that prevent them from operating as usual. They also end up spending significantly more money repairing equipment than they would have had to maintaining it.

Be Proactive Rather Than Reactive When Caring for Industrial Machinery

When you maintain industrial equipment, you are able to spot potential problems early and fix them before they become even more problematic. Something that could cost just a few dollars to fix could turn into a repair that costs hundreds or even thousands of dollars. By finding these problems early and dealing with them, you can save your company money.

Routine Maintenance is Key

You also get the option to make small repairs on your own schedule when you do proper maintenance. That won’t be the case if something breaks, since you will need to repair it right away and pay whatever it takes to get your equipment working again. When you think about it like that, doesn’t it seem silly not to take advantage of your ability to do routine maintenance on your equipment?

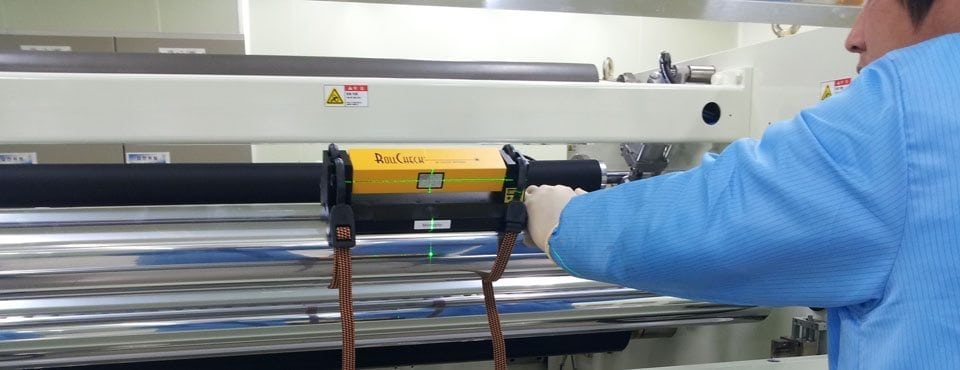

Laser Alignment Tools Keep Your Machines Running

Seifert Industrial is a company that has been helping those companies in the industrial world to maintain their equipment for more than 25 years now. We offer laser alignment solutions to those in a number of different industries, and we can offer pulley alignments systems, tension meters, crankshaft deflection products, and more to industrial companies. Thanks to our laser alignment tools, you can avoid costly repairs, which also often lead to shutdowns, and keep your equipment running seamlessly.

Our products will help you avoid We can help you avoid the need for costly repairs and show you the value in maintaining your equipment properly. Call us at 972-671-9465 or 800-856-0129 today to learn more about how we can assist you.