What are some of the most important measurement parts of a laser alignment system? There are four parts you should know about: the laser transmitter, detector, brackets and software/display unit.

Laser Transmitter

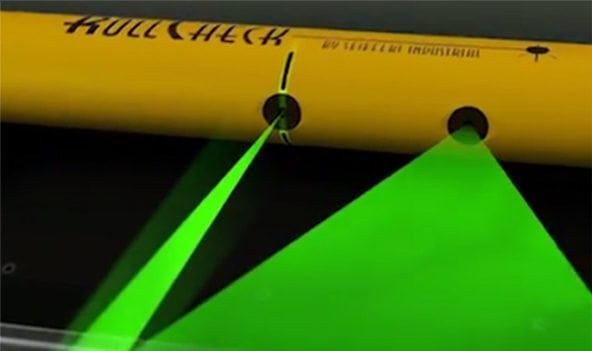

First, consider the laser transmitter. Though it may look simple, a lot of hours went into its design so that it’s stable and precise. Design can vary, of course, but basically you need and want a stable and aligned laser beam which is used as the reference for measurement. You want to trust that the transmitter was installed in a stable manner, too.

Detector

Next, consider the detector, which reads off the position of the laser beam on its surface. There are detectors that read in two dimensions/axes (at the same time) as well as single-axis units. When you have a larger surface for a detector, you have a larger measurement range.

Brackets

Thirdly, consider the brackets. These ensure that measurements can be taken correctly since transmitters (and receivers) are installed in a stable manner. Installed on measurement objects, you can trust that you get correct measurement values.

Software Display Unit

Finally, consider the software/display unit. Software runs the laser alignment system (it’s like its brain) while the display unit shows users the measurements taken and helps them figure out proper alignment thanks to displayed data. After all, the point of using laser alignment systems is to ensure perfect alignment, which ultimately saves a company time and money.

Seiffert Industrial sells high-quality, top-notch laser alignment tools. See what’s available, here.

Laser alignment tools provide precision and durability to many diverse applications. With intuitive interfaces and exceptional accuracy, Seiffert Industrial’s products help make businesses more efficient. Perhaps it’s time for your business to invest in laser alignment tools to maximize your production line? For more info, please call Seiffert Industrial, located in Richardson, Texas, at 1-800-856-0129.