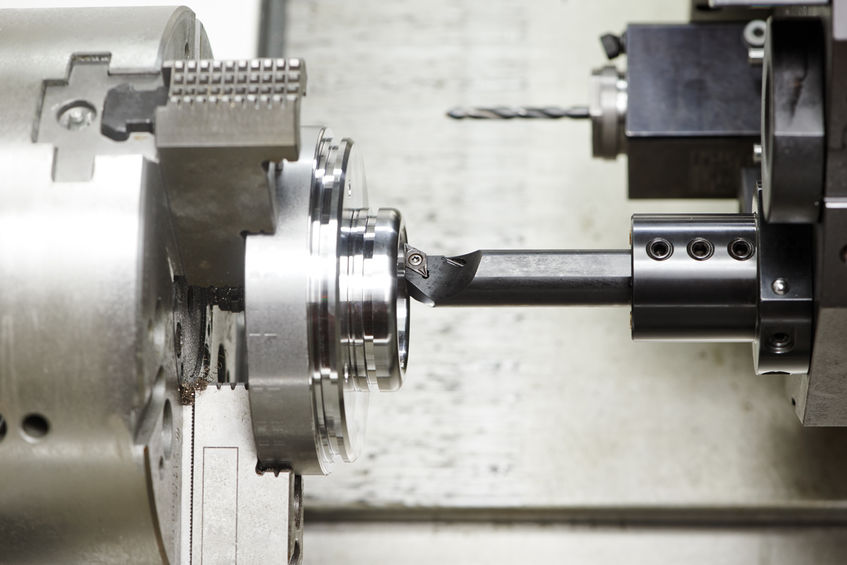

If you work with machinery, you want it to work correctly. A machine shaft needs to be positioned precisely if it’s to work as intended, and if it’s misaligned there’ll be some “symptoms” of shaft misalignment that you’ll probably notice.

You want your machinery to perform well. It needs to be reliable and you ideally don’t want premature wear happening to it, right? Shaft alignment is important; How might you know if you’re dealing with shaft misalignment? What are some things to watch for?

Determining Shaft Misalignment

To determine if the shaft is misaligned, there are five things to notice. First, look for an unusual increase in vibration. Next, listen for an unusual increase of noise during operation. Thirdly, see if there’s excessive heat generation which could mean increased friction is heating things up to the point where the equipment’s safety and efficiency is compromised. Also, look for failing seals or bearings. Finally, consider if it seems like there’s reduced operational efficiency such that the machine is using more energy than ever before and costing you more, too. If you notice these aforementioned symptoms, you probably have a shaft misalignment on your hands.

To figure out what’s going on with your shaft alignment or misalignment (as may be the case) you can use a laser technology shaft alignment tool. This will give an accurate measurement to help you determine exactly what’s good– or bad– about the situation. Using a laser tool can ultimately help you make corrections and adjustments so your alignment is perfect! Decrease downtime and increase efficiency thanks to the use of modern laser alignment tools– their accuracy will astound you.

Seiffert Industrial of Richardson, Texas, can help you choose the right laser alignment tool– call 800-856-0129 or email info@seiffertindustrial.com for more information. Seiffert is proud to be a “Made in the USA” company.