Does your company utilize a lot of equipment for production purposes? If so, it’s important for you to know the ins and outs of precision alignment. You should have a clear understanding of what it is, how it’s performed, and what effect it will have on your equipment when you utilize it. Here is a brief overview of precision alignment.

Does your company utilize a lot of equipment for production purposes? If so, it’s important for you to know the ins and outs of precision alignment. You should have a clear understanding of what it is, how it’s performed, and what effect it will have on your equipment when you utilize it. Here is a brief overview of precision alignment.

What is precision alignment?

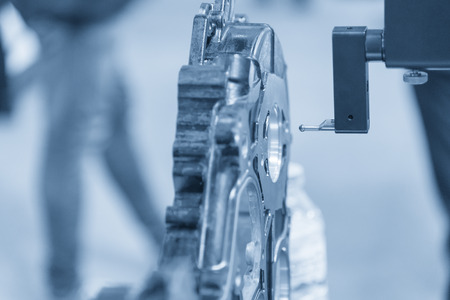

Precision alignment is a process that’s required for any equipment that’s in charge of producing things. Over time, this equipment will start to become less and less efficient when it comes to production. Parts inside of it will start to wear down, and they’ll also fall out of alignment. Precision alignment aligns them properly again and ensures that the equipment can do its job effectively.

How is precision alignment performed?

Precision alignment is performed by trained professionals who utilize a variety of tools to align the parts in equipment. They often use everything from manual tools that they must manipulate with their hands to more sophisticated tools that rely on lasers to bring the parts in a piece of equipment back into alignment.

What will precision alignment do for your equipment?

Precision alignment will benefit your equipment in a number of different ways. For starters, it’ll allow it to continue to produce products safely and efficiently. It’ll also prevent parts in it from wearing down sooner than they should. It can even help you avoid having to make costly repairs to equipment when you make it a priority.

Want to find out more about precision alignment and its many benefits? Seiffert Industrial can tell you everything you need to know when it comes to precision alignment. We can also offer the products and the services you need to carry out precision alignment in your facility. Call us at 800-856-0129 today to get started.