What is the function of laser alignment? Well, when you want to align two or more rotating shafts in a straight line, you will look at both the vertical and horizontal plane to ensure they’re rotating on a common axis. If you do this with your naked eye, you’re bound to make mistakes– our eyes are imperfect when it comes to this job. A laser alignment tool, on the other hand, was made for this purpose!

Emitters and Laser Sensors

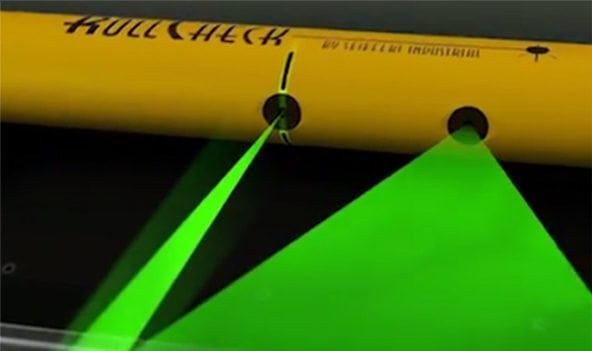

Laser alignment tools use a laser emitter and a laser sensor. The emitter shoots a laser beam across the shaft to the sensor in a single beam set-up. As that laser is emitted, the shaft gets rotated to find the center lines of rotation between the two shafts. A laser alignment tool is a precise instrument. It doesn’t make mistakes. If there’s a misalignment, the movable piece of equipment gets adjusted vertically and/or horizontally. This way, perfect alignment can be made. Software helps power this feat. Most tools perform calculations and display them graphically to show what’s going on.

Properly Aligned Machines

If machinery and equipment aren’t aligned perfectly, they will not deliver the expected results, and that costs a company time and money. Alignments should be checked every so often, since there are many reasons equipment can go out of alignment. And if/when a machine goes out of alignment, that can lead to the machine breaking down– no one wants that! Misalignments cause friction, energy loss, motor failures and other bad things.

Seiffert Industrial can help you find the best laser alignment tools to help keep your equipment working as it should, saving you money, downtime and headaches. Please call Seiffert Industrial at 1-800-856-0129 to talk about available laser and belt alignment tools. You can also use the online contact form.